Oil & Gas

Rugged Computers for Oil and Gas

FOR FIELD WORKERS WHO NEED INTRINSICALLY PROTECTED MOBILE SOLUTIONS

ANSI/UL Certification for Hazardous Locations

ANSI/UL 121201 is a widely accepted explosion-proof standard for rugged computers used in hazardous environments. This standard identifies three types of hazardous locations categorized by class, defining the general nature of the dangerous material in the surrounding atmosphere:

- Class I: Flammable gases, flammable liquid-produced vapors, and combustible liquid-produced vapors

- Class II: Combustible dust

- Class III: Ignitable fibers/ flyings

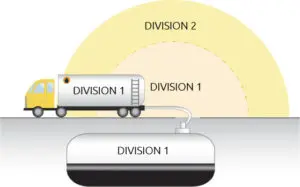

It also identifies two divisions and seven groups that indicate the level of explosive elements anticipated in each work location. Here are the division system details according to NEC article 500 through 503/CEC section 18:

- Division 1: Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors can exist under normal operating conditions.

- Division 2: Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are not likely to exist under normal operating conditions.

- Groups: Materials are further divided into Groups for Class I, Divisions 1 & 2:

A – Acetylene

B – Hydrogen

C – Ethylene

D – Propane

- Groups: Materials are further divided into Groups for Class II, Division 1 & 2:

E – Metal Dust (Div. 1 only)

F – Carbonaceous Dust

G – Non-Conductive Dust (flour, grain, wood, plastic, and more)

What is the difference between a Class I, Division 1 location and Class I, Division 2 location? What about the differences between the other locations?

Class I, Division 1 Location

Ignitable concentrations of flammable gases, vapors, or liquids:

– can exist under normal operating conditions;

– may frequently exist because of repair or maintenance operations or leakage; or

– may exist because of equipment breakdown that simultaneously causes the equipment to become a source of release.

Class I, Division 2 Location

Volatile flammable liquids or flammable gases or vapors exist, but are generally confined within closed containers;

Ignitable concentrations of gases, vapors, or liquids are usually prevented by positive mechanical ventilation; or

Adjacent to a Class I, Division 1 location where ignitable concentrations might be occasionally communicated.

Class II, Division 1 Location

Ignitable concentrations of combustible dust can exist in the air under normal operating conditions;

Ignitable concentrations of combustible dust may exist because of equipment breakdown that simultaneously causes the equipment to become a source of ignition; or

Electrically conductive combustible dust may be present in hazardous quantities.

Class II, Division 2 Location

Combustible dust is not generally in the air in ignitable concentrations;

Dust accumulations usually are insufficient to interfere with the regular operation of electrical equipment;

Dust may be in suspension in the air as the result of an infrequent malfunction of equipment; or

Dust accumulation may be sufficient to interfere with the safe dissipation of heat or may be ignitable by abnormal operation.

Class III, Division 1 Location

A location in which easily ignitable fibers or materials producing combustible flyings are handled, manufactured, or used.

Class III, Division 2 Location

A location in which easily ignitable fibers are stored or handled other than in the process of manufacture.

For C1D2 specifically, the certification covers usage in areas where combustible gases such as Acetylene, Hydrogen, Ethylene, and Propane (Groups A-D) are present occasionally. Certified C1D2 mobile devices can keep workers safe and productive for use in most specific conditions with potentially explosive atmospheres.

Environments that may require this certification include:

- Oil refineries

- Gas plants

- Mills

- Mines

- Chemical & food manufacturing

- Industrial manufacturing